Equipment

Plasma Spraying

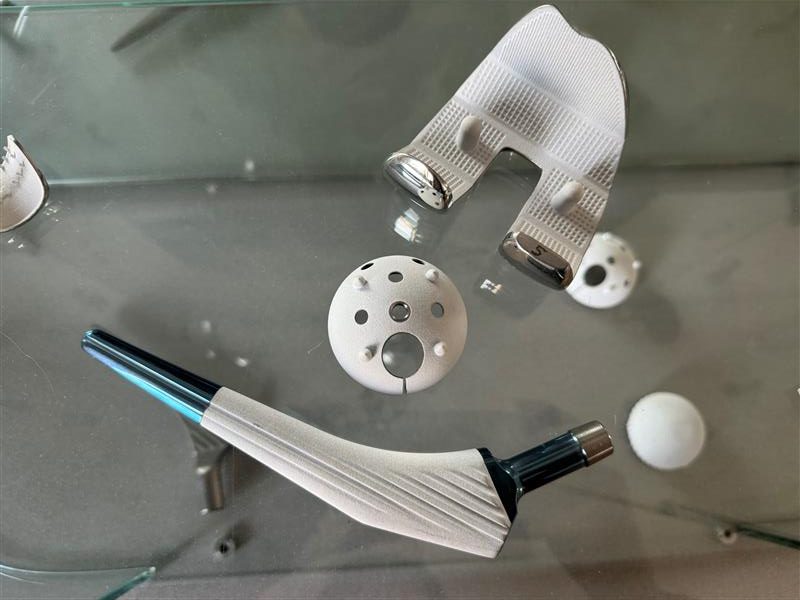

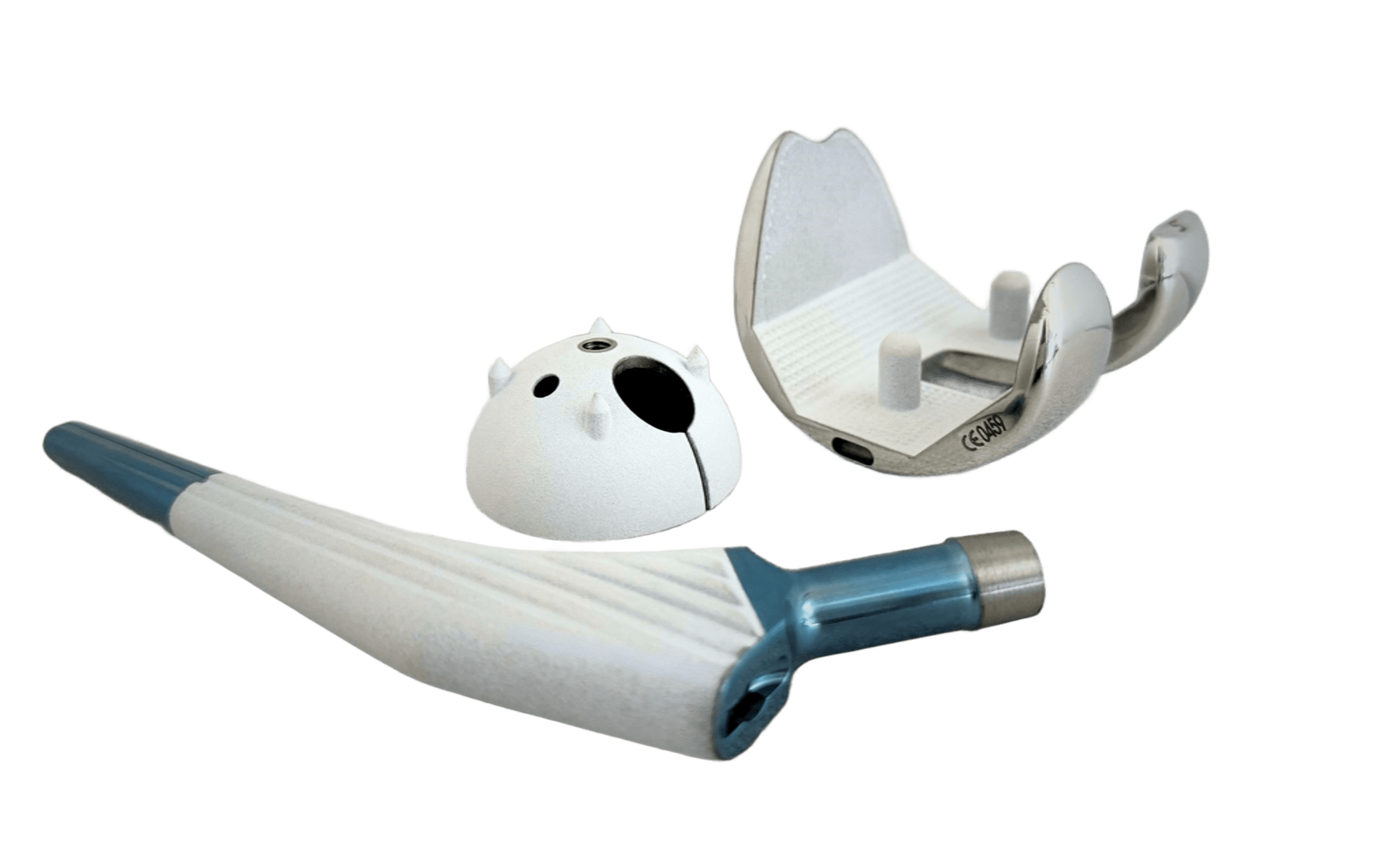

Cutting-Edge Technology for medical devices

Our plasma spraying technologies represent state-of the-art solutions for coating medical implants. This process ensures not only a durable surface but also increased biocompatibility, meeting the strict requirements of medical environments.

Through plasma spraying, we significantly enhance coating adhesion while reducing the risk of rejection by the body.

Benefits of Plasma Spray Coatings

Adhesion and Durability

Excellent bonding for long-lasting

Material Versatility

Compatible with a wide range of substrate materials, including metallic and ceramics

Biocompatibility and Safety

Reduces rejection risks and ensures optimal integration in biological human environment

Enhanced Performance

Improves osseointegration for better implant efficiency

Atmospheric Plasma Spraying (APS)

This process is the most commonly used plasma spray technique, enabling coatings to be applied to a broad and diverse range of materials, including metals and ceramics in an atmospheric environment.

The APS process minimizes the formation of non-metallic inclusions in metallic coatings, ensuring a high-quality finish.

Advantages of APS Technology:

- Protects surfaces against wear corrosion

- Shields surfaces against oxidation

Our workshop is equipped with four Atmospheric Plasma Spraying systems to ensure productivity.

Vacuum Plasma Spraying (VPS)

This process is carried out under a vacuum-controlled atmosphere at low pressure and is suitable for metallic coatings, making them free of non-metallic inclusions such as oxides or nitrides.

Advantages of VPS Technology:

Produces high-quality coatings with reduced non-metallic inclusion content and controlled porosity, tailored to the specific requirements

Our workshop is equipped with two Vacuum Plasma Spraying systems to ensure productivity.

Optimize Your Coating Process

Our cutting-edge plasma spraying and surface treatment equipment ensures precision, reliability, and optimal performance for medical implants. Trust in our expertise to meet the highest standards in the industry.

Corundum Blasting Equipment

Corundum blasting presents various advantages :

- Corundum removes all traces of oxidation.

- Corundum blasting easily strips stubborn surfaces.

- It allows to create a tailored surface roughness.

- It is suitable for biocompatible materials.

We are equipped with seven corundum blasting equipments, one automatic and six manual ones.

Cleanrooms

- Room 1: Deburring and cleaning of titanium coating

- Room 2: Deburring and cleaning of Hydroxyapatite (HAP) coating

- Room 3: Final Control & packaging room

Rigorous quality controls are done regularly through various air and surface samplings.

Powders

HAP

Hydroxyapatite (chemical formula: Ca10 (PO4)6(OH)2) is one of the commonly used active bioceramics to spray coatings for bone implants, thanks to the interface formed by the living tissue that develops in its pores and allows osseointegration (bone growth). This technique prevents the use of cement to fix the prosthesis.

TITANIUM

Titanium and its alloys, mainly TA6V (Titanium 6 Aluminum 4 Vanadium), are known for their chemical, physical, and mechanical properties suitable for implantation in the human biological environment. Its advantages include corrosion resistance, relatively low density, low modulus of elasticity, mechanical strength, and high wear resistance. The porosity developed during the deposition of the coating allows mechanical adhesion from the prosthesis to the bone.

Both HAP and titanium can be deposited using APS and VPS techniques.

Any Question ?

Contact us, we are available to answer all your questions.

We will get back to you as soon as possible.